Accurate Bushing Company was founded in 1983 in a small warehouse in Garwood, N.J., with the goal of becoming a leader in the replacement bearing industry.

For more than four decades, the company has developed a talented and dedicated staff that has allowed Accurate Bushing Company to become a leader in the bearing and power transmission industry throughout the United States.

Today, it has a proven record of supplying the highest quality products at the lowest possible prices with an eye on value to its diverse customer base.

Structured for responsiveness

Accurate Bushing Company’s Smith Bearing Division has developed a network of industrial and aerospace distributors, manufacturing plants and sales offices throughout the world. This responsive network includes IDC members.

“The structure of our operation affords us the ability to give highly personalized attention to every customer. Most importantly, this structure gives us the ability to respond immediately to our customers’ requests as well as providing highly cost-effective products,” says Peter Dubinsky, Accurate Bushing Co. CEO and President

The company structure affords the ability to give highly personalized attention to every customer, says Dubinsky.

With its award-winning sales team and “do what it takes attitude” of everyone in the organization, the Smith Bearing division offers the highest quality customer service possible. “We know time is money, so we strive for error- free, same-day service from our Garwood, N.J. warehouse,” says Dubinsky. “We also have made our online interchange catalog available 24/7, which supplies valuable information whenever customers – our No. 1 priority – need it.”

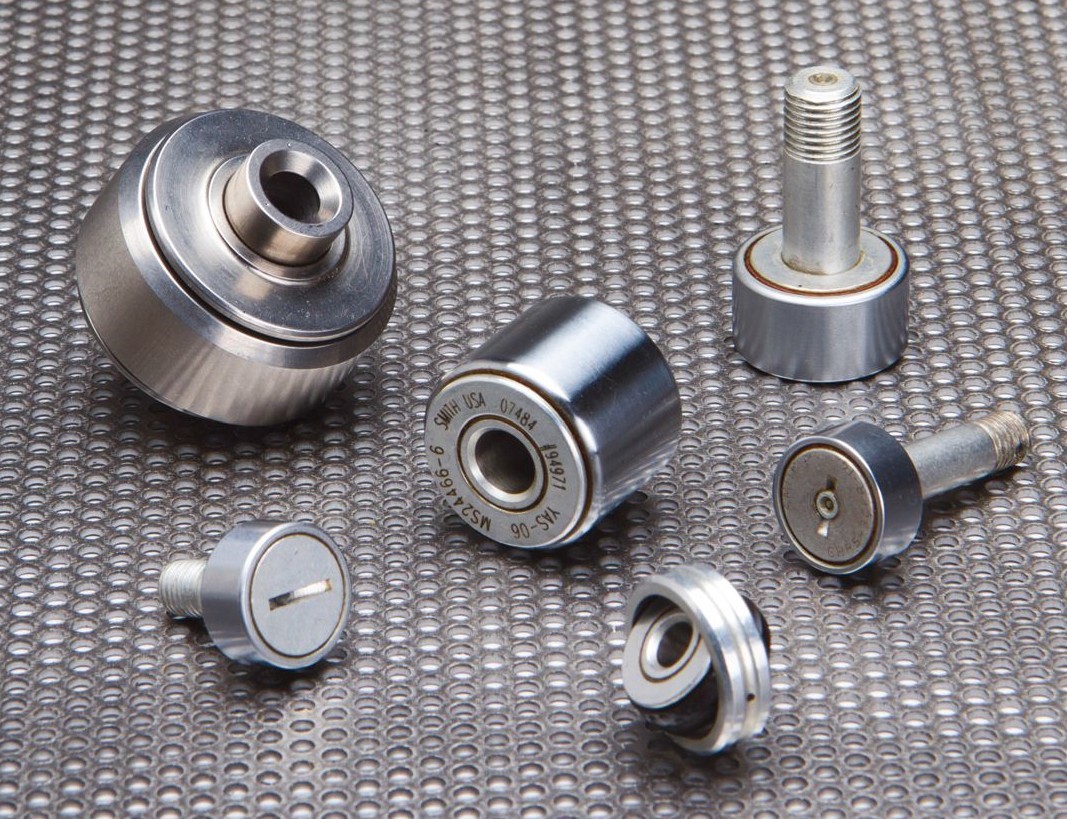

From electric motor-grade bearings to bearings that meet demanding aeronautic and military requirements, Accurate Bushing’s Smith Bearing line can meet even the most demanding specification. Smith Bearings are available in:

- Cam follower needle roller bearings in inch and metric sizes

- Stainless steel cam followers for special corrosive applications

- Cam followers with self- lubricating engineered plastic bushings

- Smith-Trax branded bearings with tapered roller bearings and deep-groove ball bearings for high-thrust load applications

- Aerospace- and military- approved needle roller bearings for engine and airframe applications

- Spherical plain bearings

- Drill jig bushings

- Specialty aerospace products and assemblies

ISO registered

Accurate Bushing’s Smith Bearing division has received ISO 9001 and AS 9100 quality registrations in recognition of its continued commitment to world- class quality control systems.

“Our quality system is recognized by General Electric, Lockheed, Boeing Aircraft Corporation, British Aerospace, as well as many other military and aerospace companies. Our military bearings meet the requirements of Mil-B-3990 (SAE AS 39901). This level of quality certifications and approvals assures our customers unequaled dependability of our products,” Dubinsky says.

Custom capabilities

Even with the wide variety of bearings and other power transmission products in stock, customers have also come to expect that Accurate Bushing can deliver custom-made components and assemblies.

“Over the years, our priorities and focus have not changed: Quality-Price-Service. That is what we stand for at Accurate Bushing Co. We are proud to say we are your value leader in the bearing industry”

Highly experienced Accurate Bushing Co. engineers can work closely with end-users and original equipment manufacturers (OEMs) to develop and offer the best solution for their bearing requirements. These engineers have extensive knowledge of available metallurgies so they can offer customers the best suitable material for special designs and applications. The company regularly custom- manufactures bearings in a wide range of materials including high-carbon alloy steels, stainless steels, tool steels and exotic alloys.

“Our advanced metallurgical department routinely verifies and tests all raw materials, plating and heat-treating processes used in the manufacturing process of our products,” Dubinsky adds.

There’s a Smith Bearing for your application. Accurate Bushing’s responsive customer service team can help you whether your power transmission need is off-the-shelf or a custom build with exceedingly tight tolerances

This careful analysis and scrutiny in each phase of the manufacturing process assures proper conformance to all aerospace requirements and guarantees that only materials meeting Accurate Bushing Co.’s rigid standards are used in Smith Bearing products.

Accurate Bushing’s Smith Bearing division also has the ability to manufacture a variety of custom bearing assemblies. “Typically, this entails the precision machining of a bearing housing and the assembly of needle or ball bearings into the housing. By controlling the entire design and manufacturing process of a custom order, Smith Bearing can guarantee the quality, performance and delivery of an assembly. We can perform all aspects of such projects from design to finish, including the machining process, applications of special coatings and plating, assembling and testing of the final product,” Dubinsky says.

Smith-Rail hardened steel rails

Precision-manufactured Smith-Rail hardened steel rails drastically reduce system design time and sourcing costs of guidance systems for material handling equipment. Engineered to be used with heavy-duty Smith-Trax track rollers, the steel rails are fabricated from 180,000

psi tensile strength steel in three profiles to maximum lengths of 12 ft. The exclusive Rail-Bearing contact surfaces are hardened to 60-65 Rc to match the stength of Smith-Trax V-groove, plain and flanged bearings and can take up to 71,500 lbs. loads per roller. Available with drilled, counter bored and tapped mounting holes if desired

Smith Bearing has a fully integrated manufacturing facility capable of producing high-precision needle roller bearings that meet aerospace and industrial requirements. “Our computerized CNC grinding and precision machining centers are considered to be the most advanced in the industry,” Dubinsky says. Its facilities are capable of manufacturing a wide range of products to exacting tolerances required by customers around the world.